Egg Tray Manufacturing Process

- By capricornrfyhj dahquoh

- •

- 06 Apr, 2021

- •

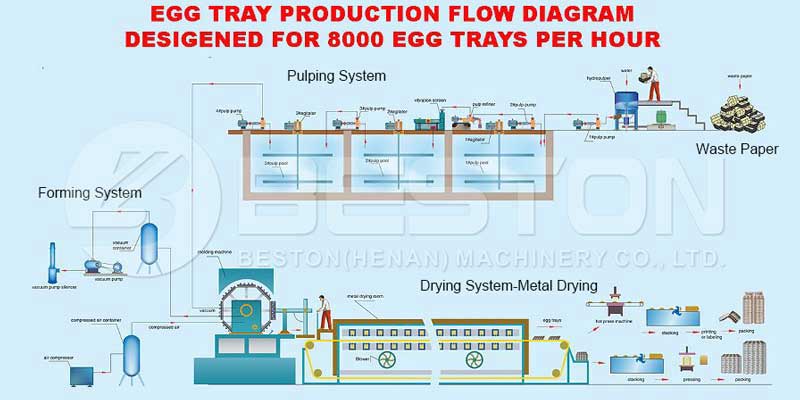

Pulp Making.

The development of pulp will be the starting point of your paper egg tray manufacturing process. This phase is vital. You need to pay utmost attention here. Otherwise, the other steps become unsuccessful. At the first instance, you will place the raw material into an empty container. Add water in appropriate amounts depending on the part of the waste paper accessible. The approach ensures the procedure becomes more efficient. Also, you avoid the wastage of water over time. Let the paper soak the liquid, then use a pulp beater to create a consistent mixture. Continuously smash the pulp to get rid of any lumps. It shouldn’t be too runny nor too thick.

Molding.

Molding is really a process the location where the mixture from the initial step takes the design from the different molds. The egg trays making machine is quite versatile. It can make end products trays to carry apples, shoes, and even coffee cups. When the pulp achieves the specified state, it gets transported one stage further through pipes. The devices will release the mix under pressure because they land in the available forming molds. Once the distribution is even, you employ a vacuum pump to suck out any air making the pulp take the exact shape. The end result is high-quality egg trays. The stage can take a moment, depending on the number of production. The final bit involves blowing air to detach the already formed paper egg trays. Please read the info about how to make egg trays manually.

Drying.

Even though the egg trays might seem to be ready, they still contain a amount of excessive water. The drying systems work effectively to remove this moisture content. You can find three options, including metal, brick, and natural drying. These work differently. Thus, you have to choose wisely. Brick and metal drying systems are the most beneficial and suited to large production. However, you will need to invest more money to acquire them. Natural drying occurs on a sunny day. It is actually cheap, but it arrives with many limitations.

Packaging.

The final phase involves passing the egg trays via a hot press. These devices will eliminate any air-spaces to offer the egg trays the same and defined look. At a later time, they get packaged then shipped for the various clients.

The above mentioned information will enlighten you on the numerous step working in the egg tray manufacturing process. Each step is vital and needs an identical amount of attention.